JPMA Awards

About the JPMA Awards

The JPMA Awards started in 1979, and is the 47th in 2025. The purpose of the JPMA Awards is a spread of the PM industry.

Categories of the JPMA Awards are as follows.

・New Products (New Design/New Materials/Process Development)

・New Powders

・Equipment Development

Since 2003, the Grand Prix has been given to an especially excellent product.

Effort Prize has been given to some products with the feature from among a left out of selection products.

Search is available for JPMA Award-winning product from last several decades

The number of available:Records1-5 of 5

New Design

2025

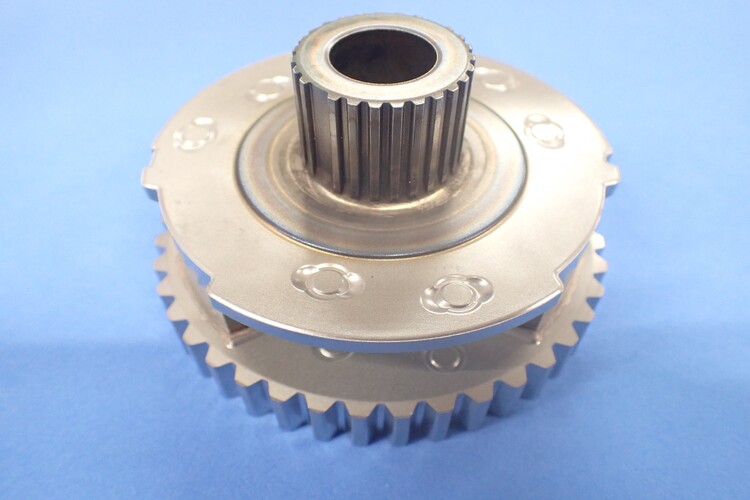

Sintered spur gear for EV cooling module using high-airtightness heat-treated material

- DIAMET CORPORATION

The achievement of demanding quality requirements—including intricate shape formation, airtightness, strength, and hardness—through the optimized combination of quenching, steam treatment, and special cleaning processes was recognized. As demand for BEV cooling modules is expected to grow, this technology is anticipated to expand to similar products and contribute to the broader adoption of high-strength, airtight components in other applications.

Process Development

2025

Development of Soft Magnetic Composites Core with Ultra-thin, High-withstand-voltage Insulation Coating to Enhance the Motor Performance

- SUMITOMO ELECTRIC INDUSTRIES, LTD.

The development of a new insulating resin solution for the surface of SMC cores, along with optimization of the coating process and the formation of an adherent thin film through controlled chemical reactions with the core material, has achieved three times higher insulation voltage at one-tenth the cost. Mechanical strength is also maintained, and the technology is expected to contribute to the wider adoption of axial gap motors in the future.

Development of a Labor -Saving Production Line for Sintered Brazing Carriers

- SUMITOMO ELECTRIC INDUSTRIES, LTD.

Sintered carriers have been used for many years, and their production methods are well established. The integration of material fabrication, heat treatment, and inspection into a continuous production line has significantly reduced work-in-process inventory, shortened lead time, ensured consistent quality, and achieved a 30% cost reduction. The fact that mass production has reached a level of 70,000 units per month is a remarkable accomplishment, and further expansion of the sintered carrier market is anticipated.

New Powders

2025

Nickel-free low alloy steel powder realizing the production of high-strength sintered components

- JFE Steel Corporation

Developing an Fe–Mo alloy steel powder that realized strength, hardness, and fatigue strength equal to or greater than those of conventional 4Ni partially diffusion-alloyed steel powders, despite being Ni-free was recognized. This was realized through optimization of particle sphericity and refinement of Cu powder. The technology also achieved a 20% cost reduction and reduced environmental impact. As an alloy steel powder that balances environmental performance, quality, and cost, it is expected to see growing market adoption in the future.

Effort Prize

2025

Sintered Guide Bushings for Electric Capacity Control Valves (ECV) in Automotive Air Conditioning Compressors

- Porite Corporation

This achievement was recognized for replacing conventional machined brass components with a sintered Cu–Sn–P–C material containing dispersed solid lubricant (graphite), resulting in a 50% cost reduction. With an annual production volume of 3.68 million units, the technology demonstrates strong mass-production capability, and further adoption of sintered bushings is expected as the use of electronically controlled capacity valves (ECVs) continues to expand.

Japan Powder Metallurgy Association

Japan Powder Metallurgy Association